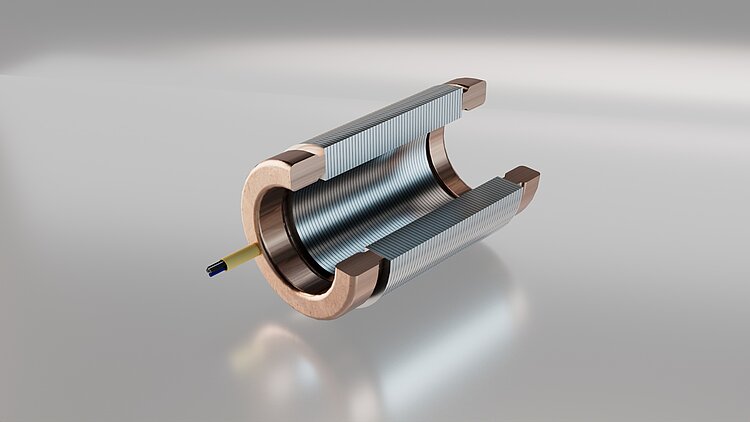

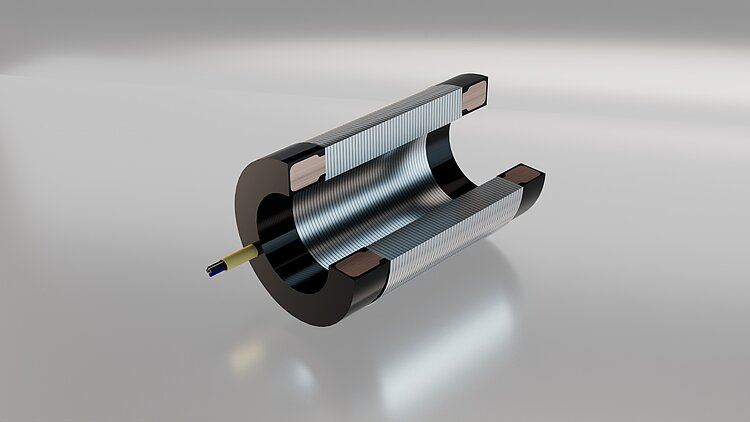

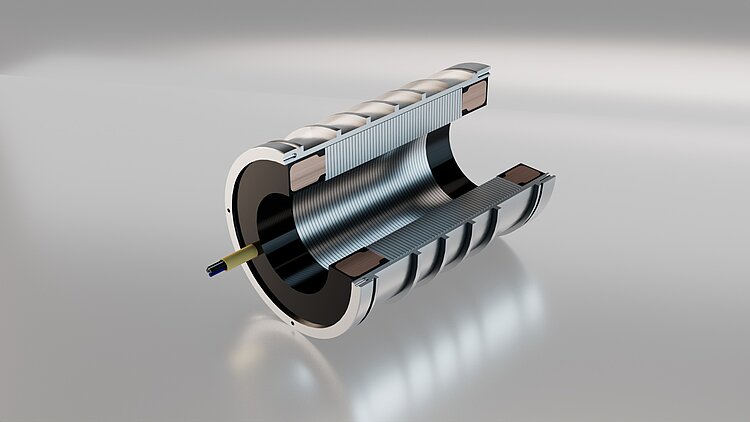

Induction motors

The induction motor components are an aproven motor concept. This drive technology is often favoured due to its proven robustness and high performance. This technology also boasts an excellent price-performance ratio.

Our performance ranges for asynchronous motor components:

- Stator diameter: 24–640 mm

- Speed range: up to 300,000 rpm

- Output power: up to 500 kW

- Continuous torque: up to 5,000 Nm

Our experts are happy to assist you in your selection. Get in touch now!

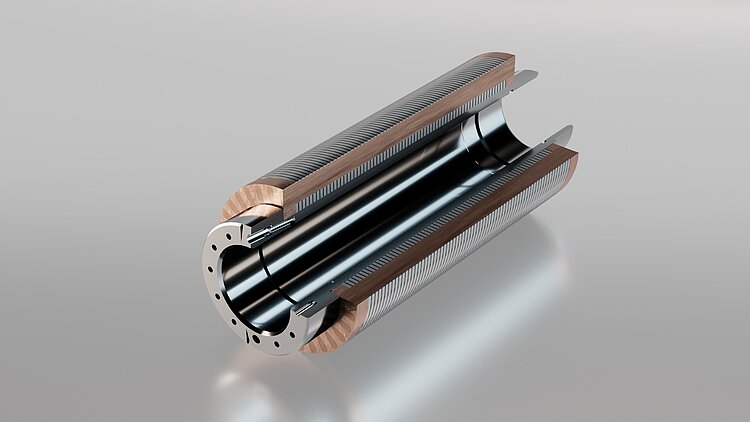

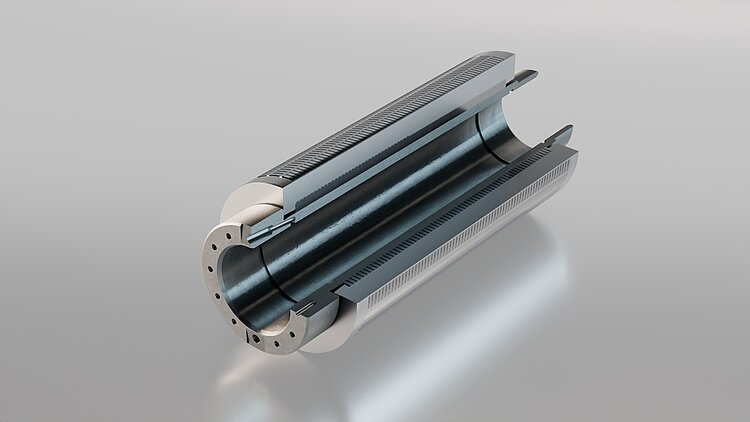

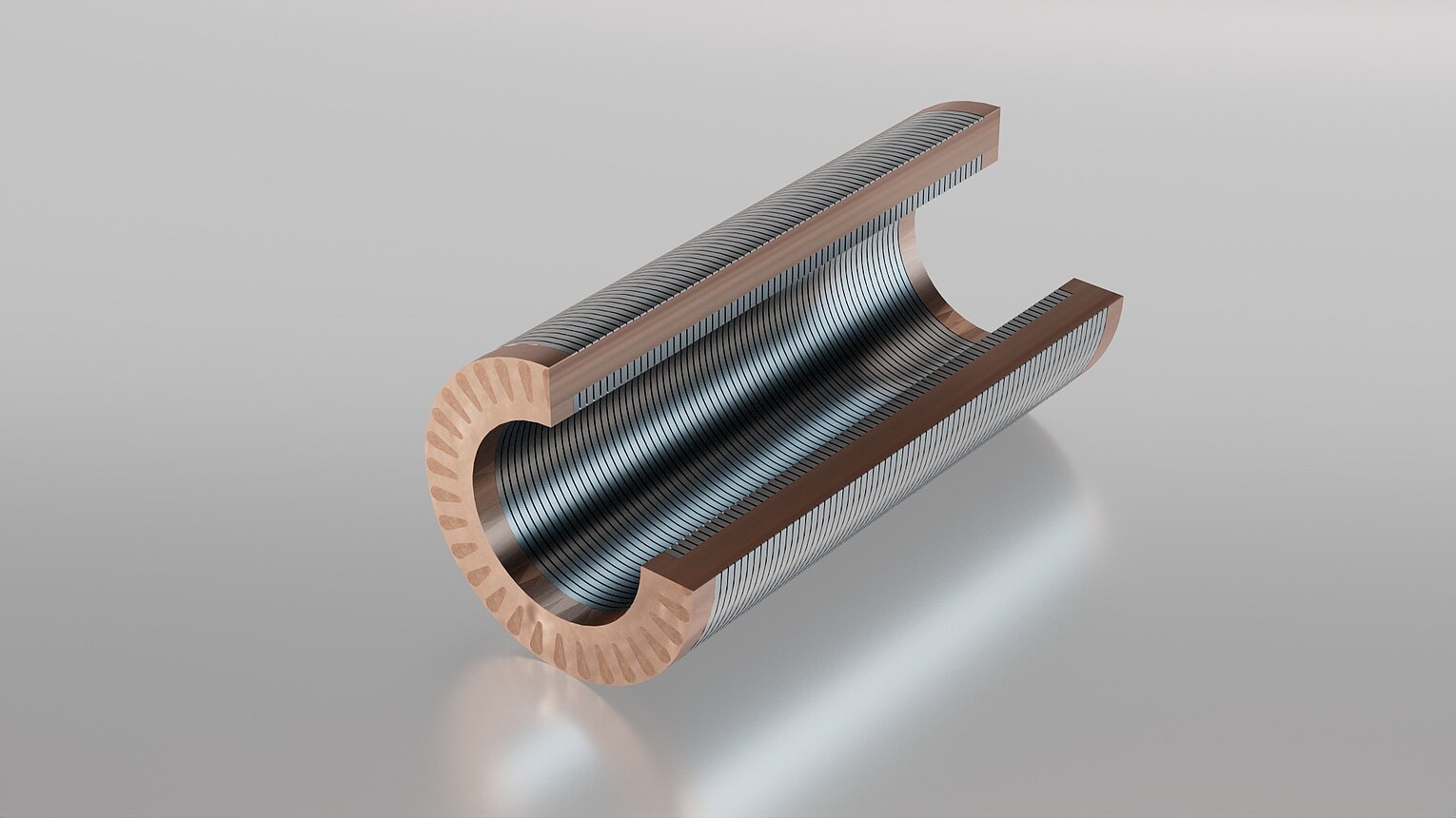

- For the high(est) speeds

- The very largest shaft diameters can be achieved

- High efficiency

- Flexible length scaling

- Design with high-strength retaining rings possible

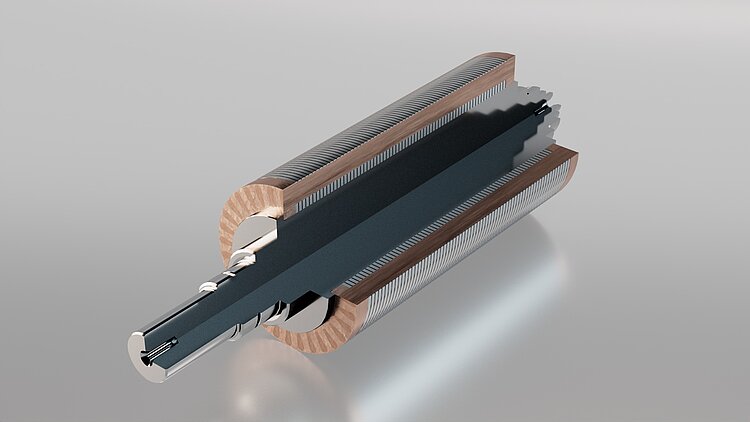

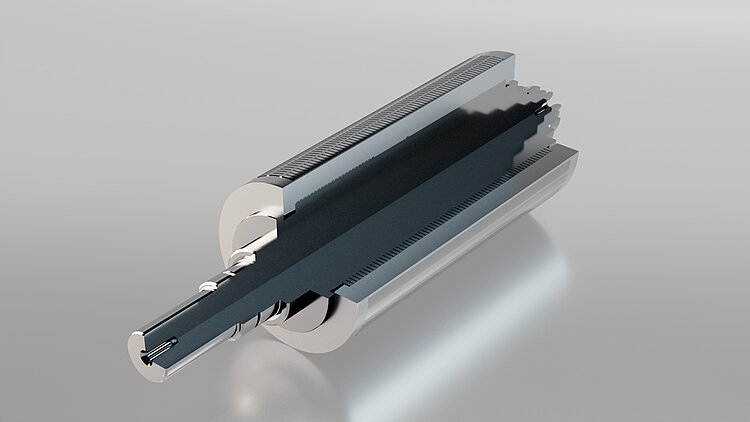

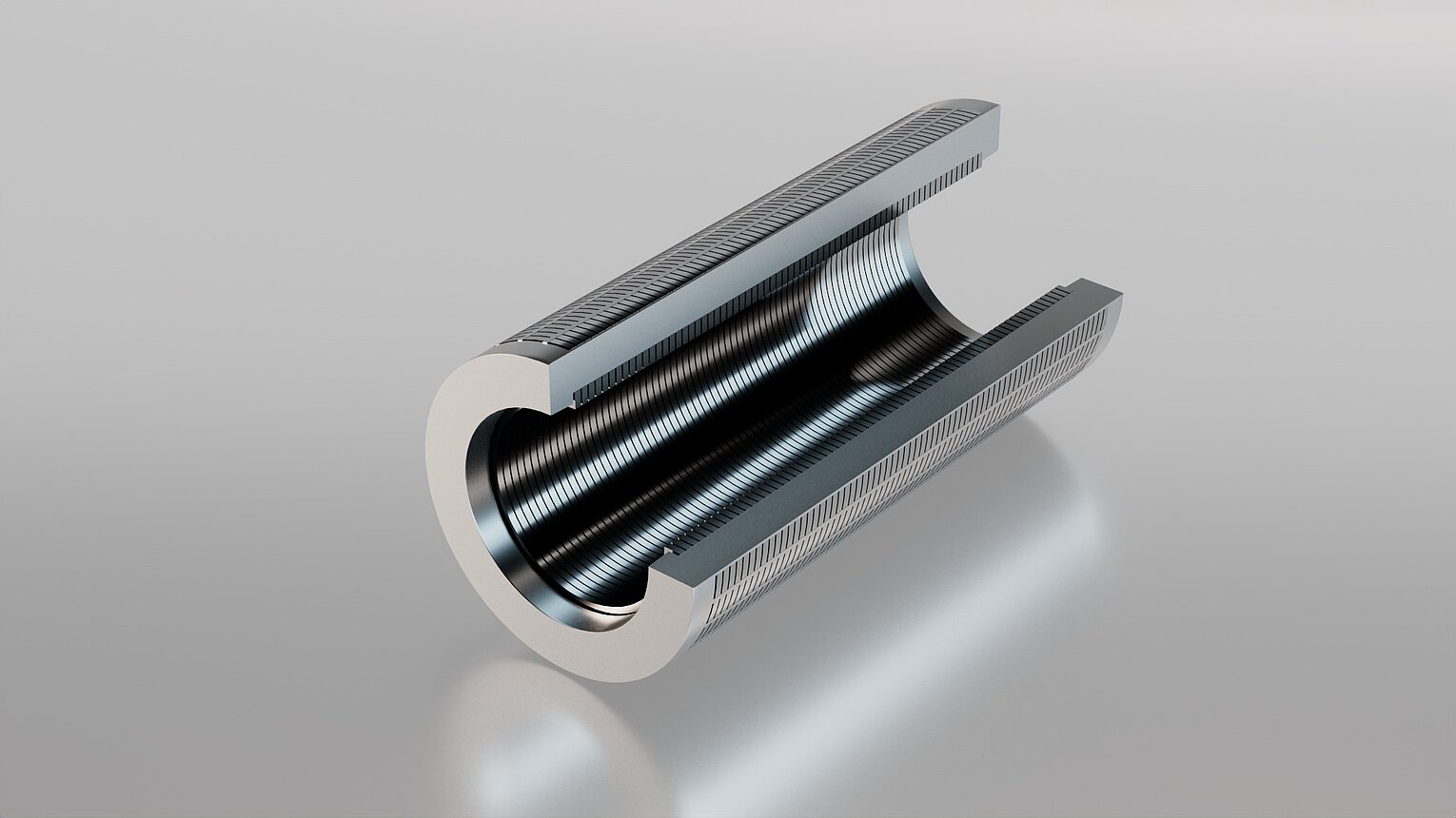

- For the high(est) torques

- Highest efficiency

- Large shaft diameters can be achieved

- Flexible length scaling

- Design with high-strength retaining rings possible

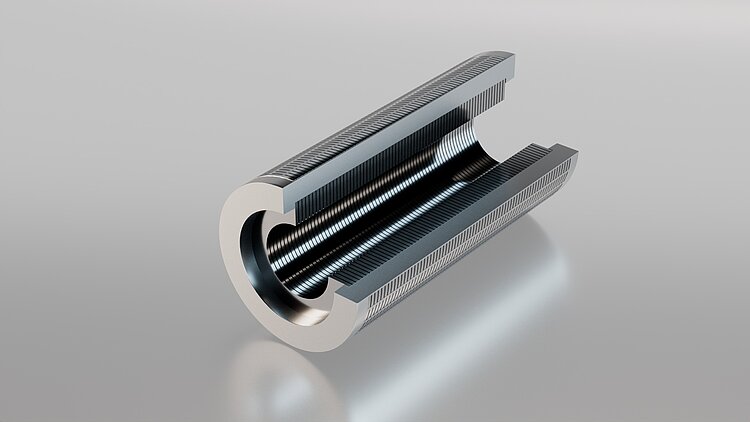

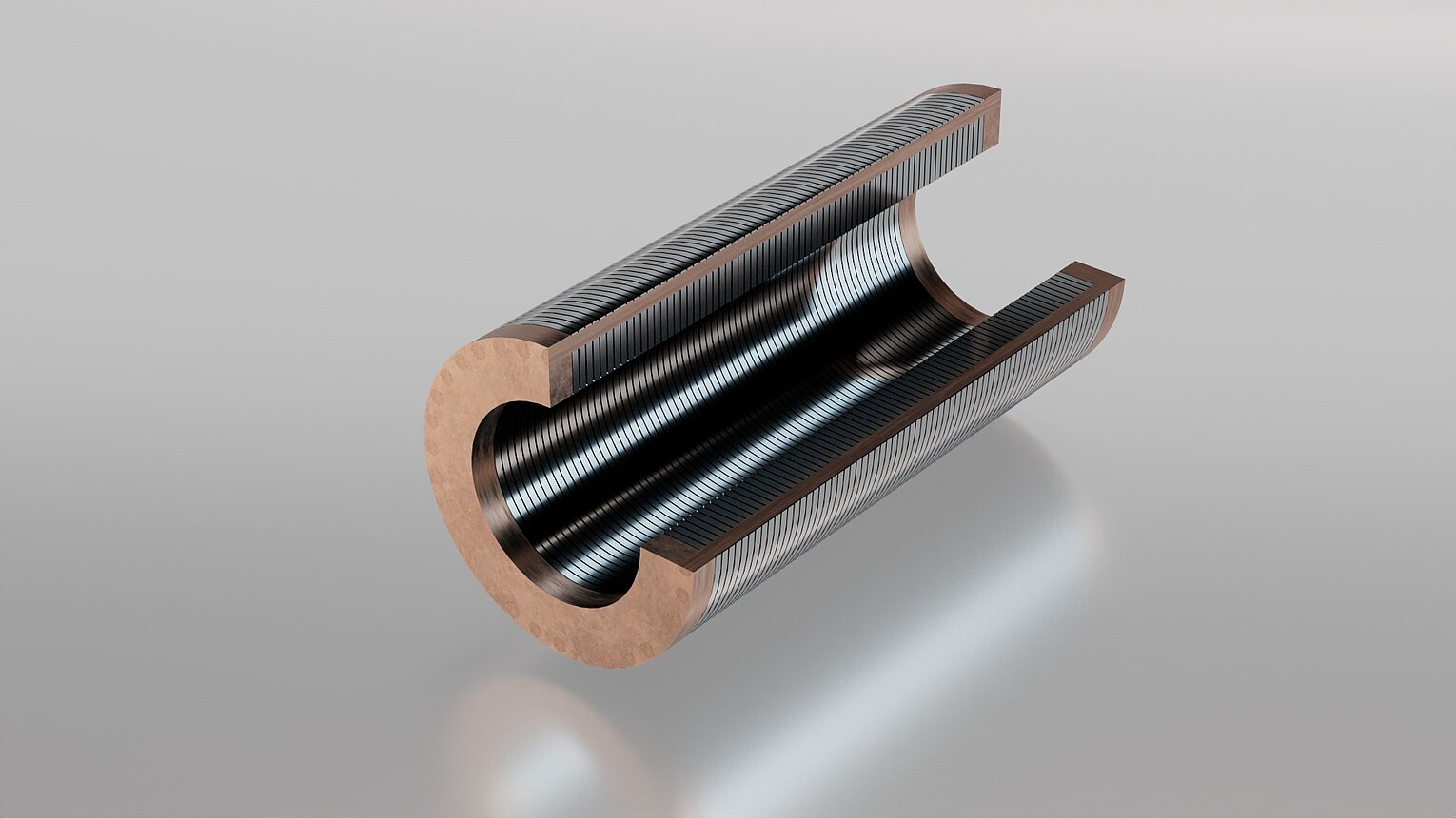

- For high speeds

- For high torques

- High efficiency

- Design with high-strength retaining caps possible

- Commercial series production

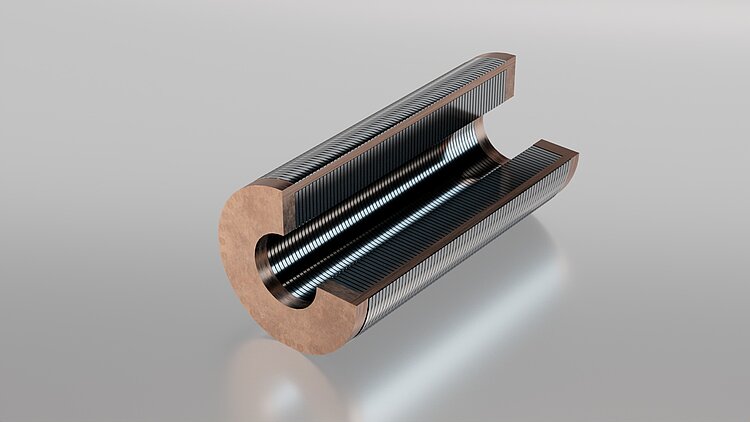

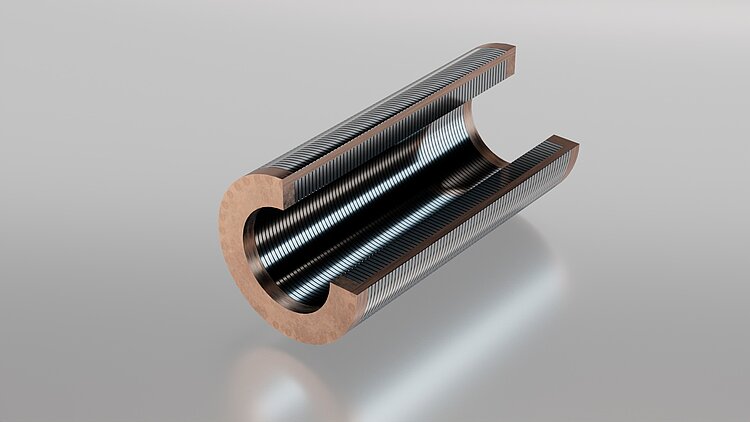

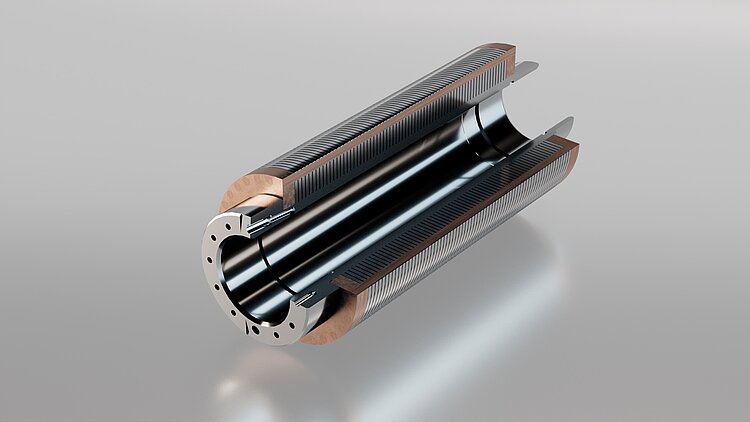

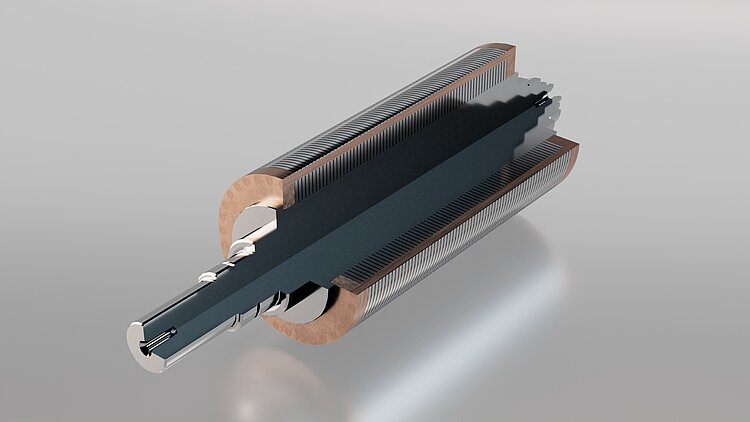

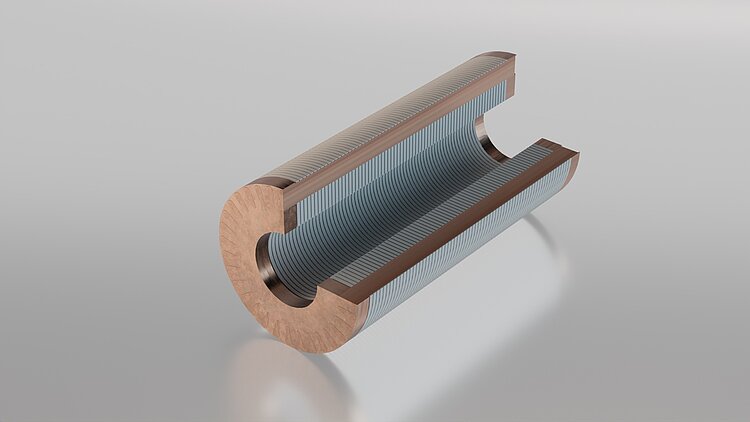

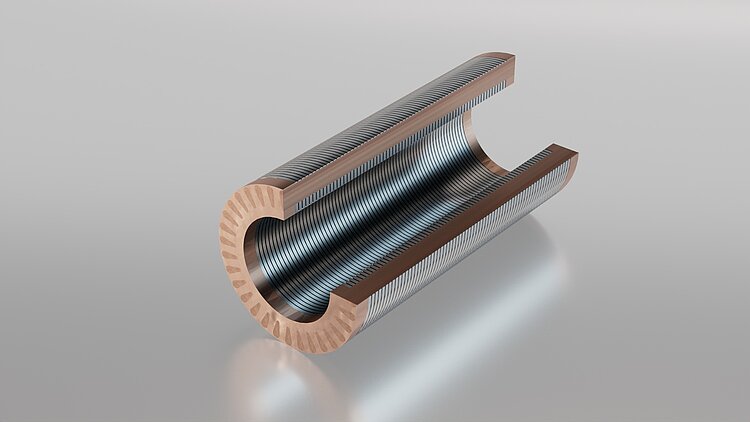

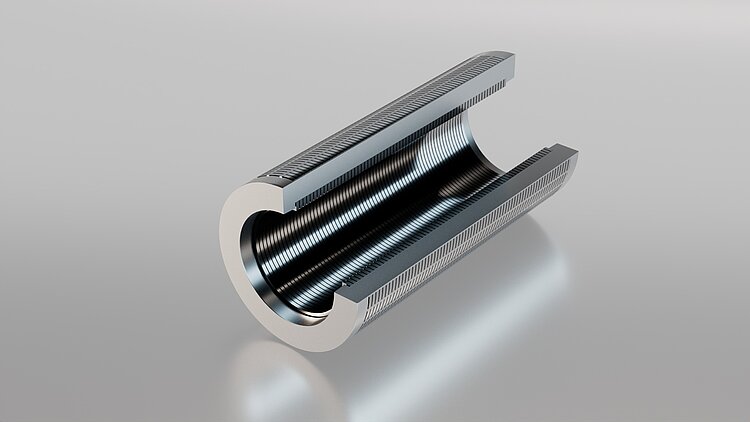

Stators

Copper round bar rotors

Copper profile bar rotors

Aluminum die-cast rotors

Get in touch with our specialists:

Call us on

+49 (0) 7561-98248-27

Send us a message to

m.horn(at)ate-system.de