Synchronous motors

Due to their technology, synchronous motors generally have advantages over other motor technologies. Their simple operating principle allows the technology the best torque density and highest efficiency. Different topologies serve all requirements.

Our performance ranges for synchronous motor components:

- Stator diameter: 8–1600 mm

- Speed range: up to 1,000,000 rpm

- Output power: up to 500 kW

- Continuous torque: up to 30,000 Nm

Our experts are happy to assist you in your selection. Get in touch now.

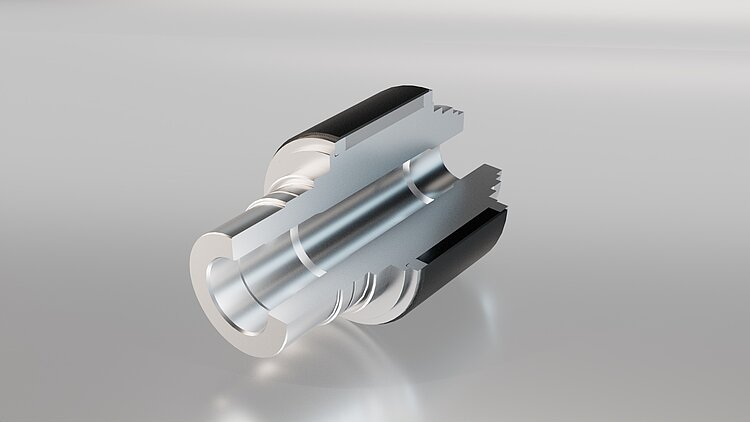

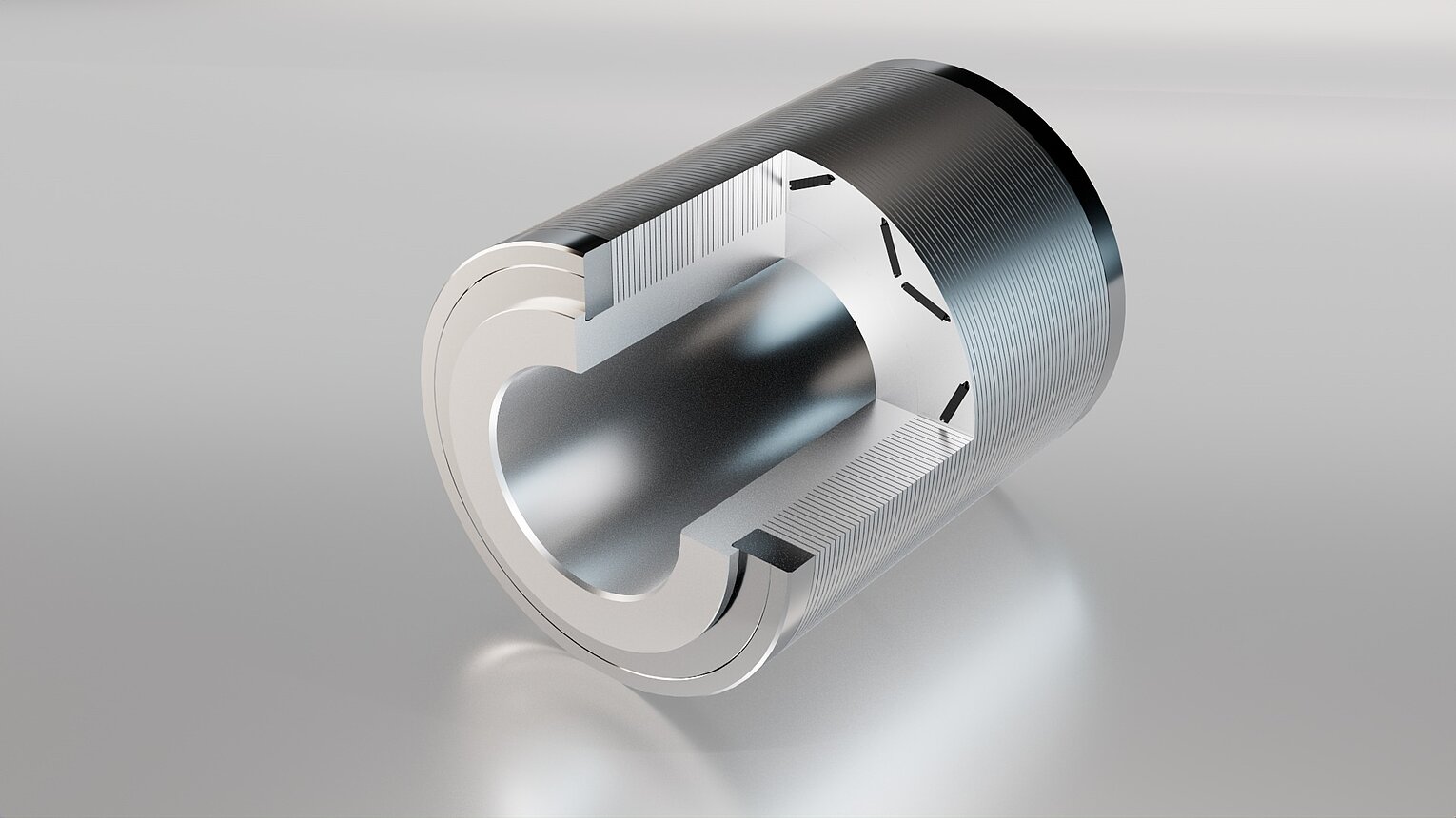

The permanent magnet mounted on the rotor surface allows the highest torque density to be achieved. This allows us to build drives that have the highest efficiencies, even in the small(est) sizes.

- For the high(est) speeds

- For the high(est) torques

- The very largest shaft diameters can be achieved

- Highest efficiency

- A choice of retaining materials for all requirements

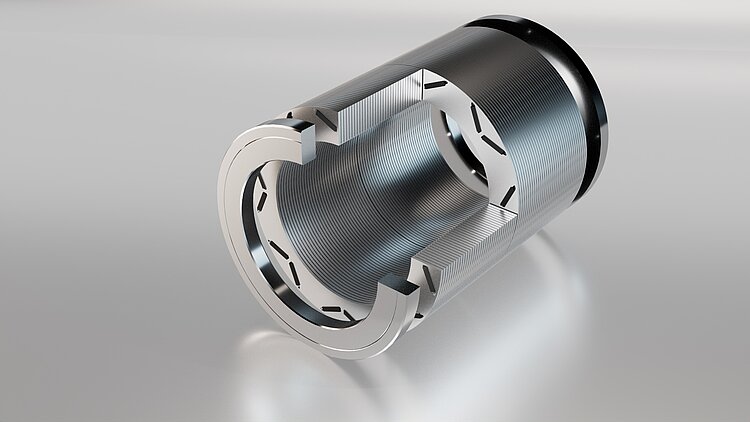

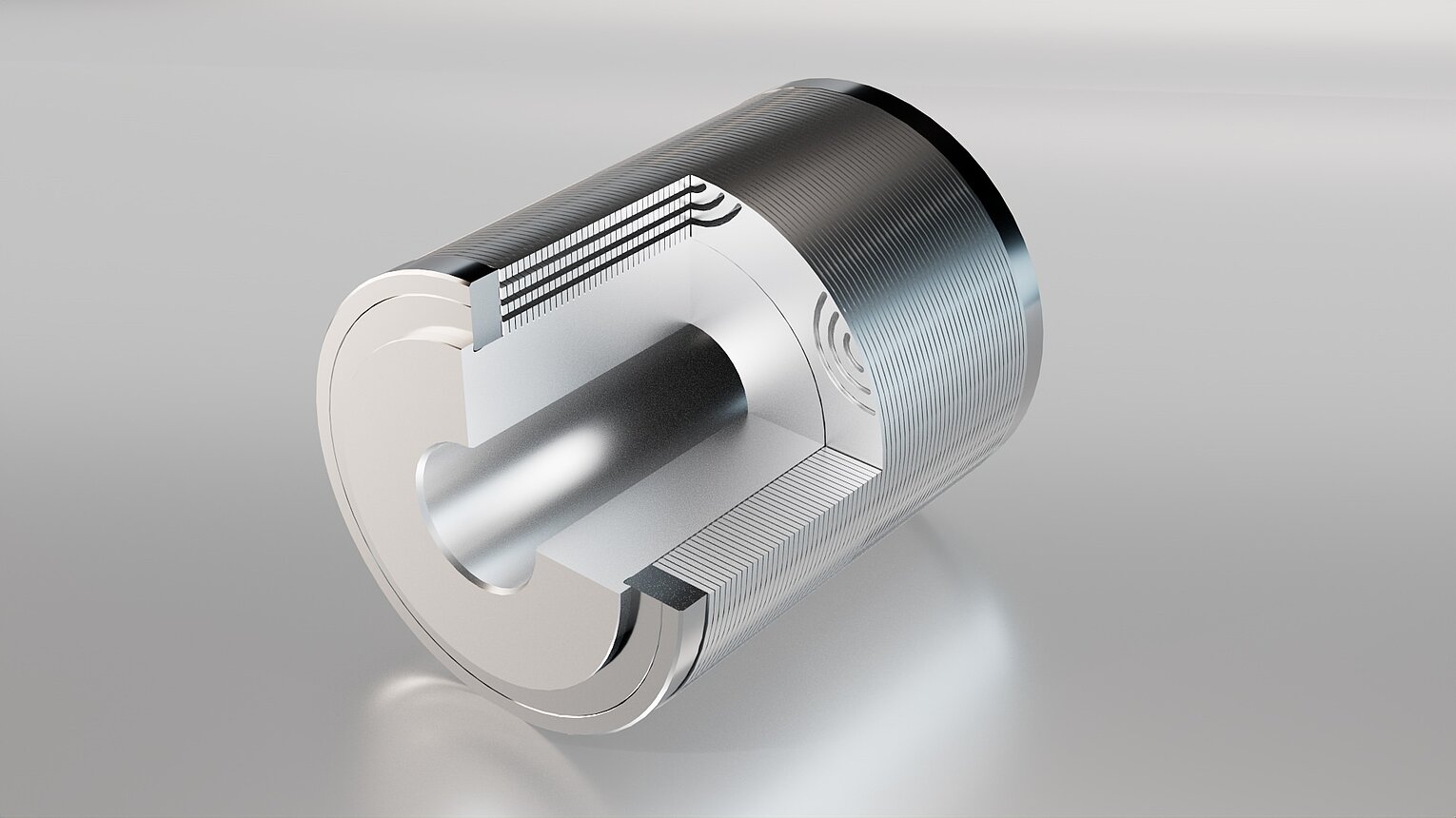

Due to the permanent magnet embedded in a laminated rotor structure, a reluctance torque can also be used. This means that only part of the torque is generated by the permanent magnet. This topology is characterised by a large field weakening range and high torque density at the same time.

- Less magnetic material due to the use of reluctance moment

- Wide field weakening range

- High efficiency

- Freely selectable interface to the shaft

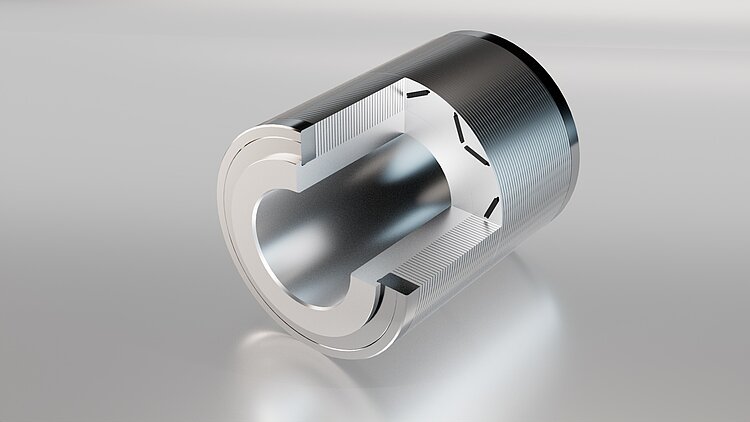

The synchronous reluctance motor is suitable as an economical solution for applications with low torque density. This technology is characterised by a very simple rotor topology with the lowest rotor losses.

- No permanent magnet material required

- Wide field weakening range

- Lowest rotor losses

- No idling losses

- Freely selectable interface to the shaft

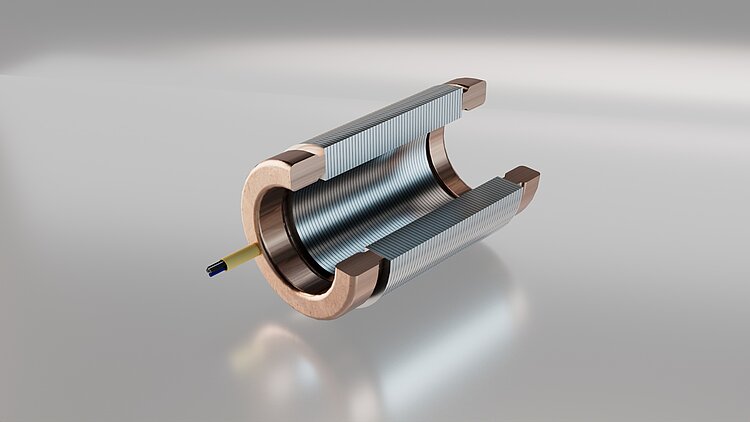

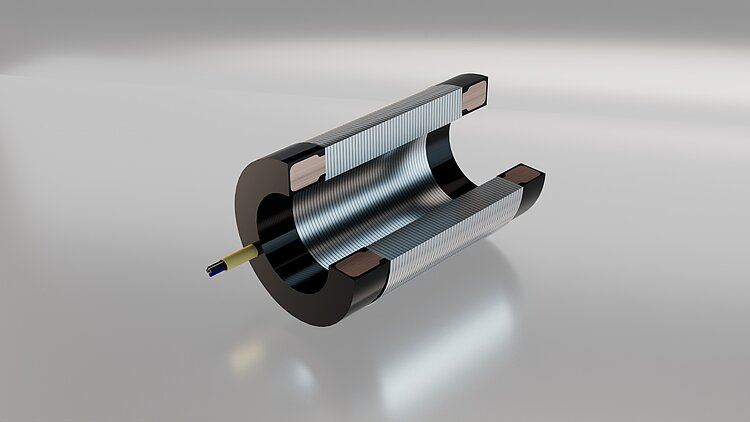

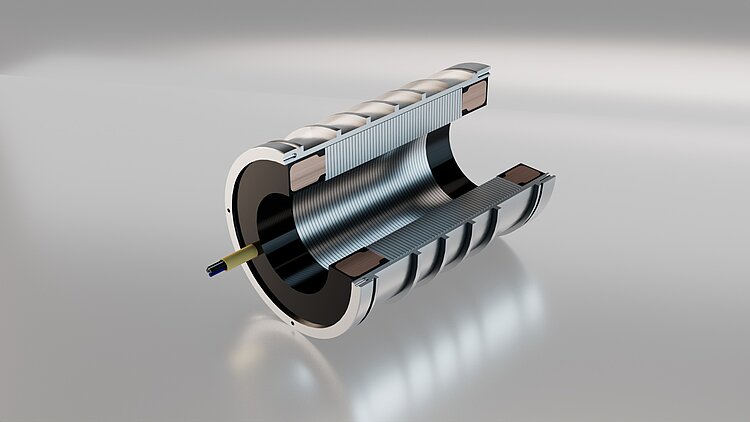

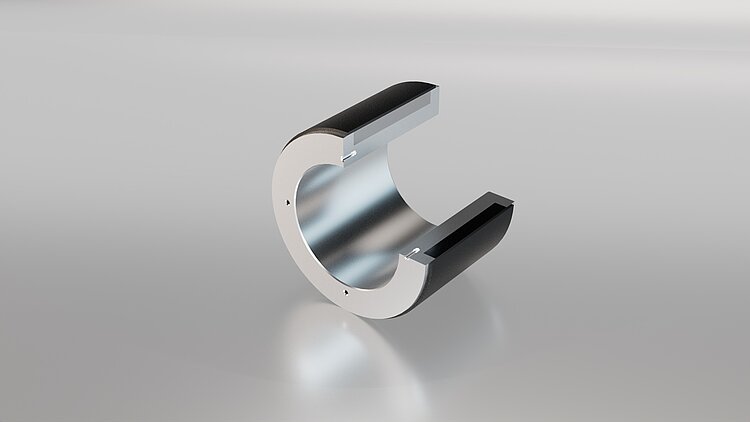

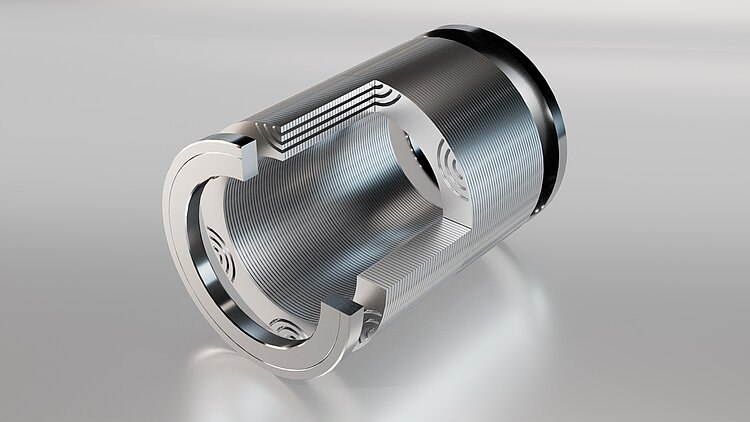

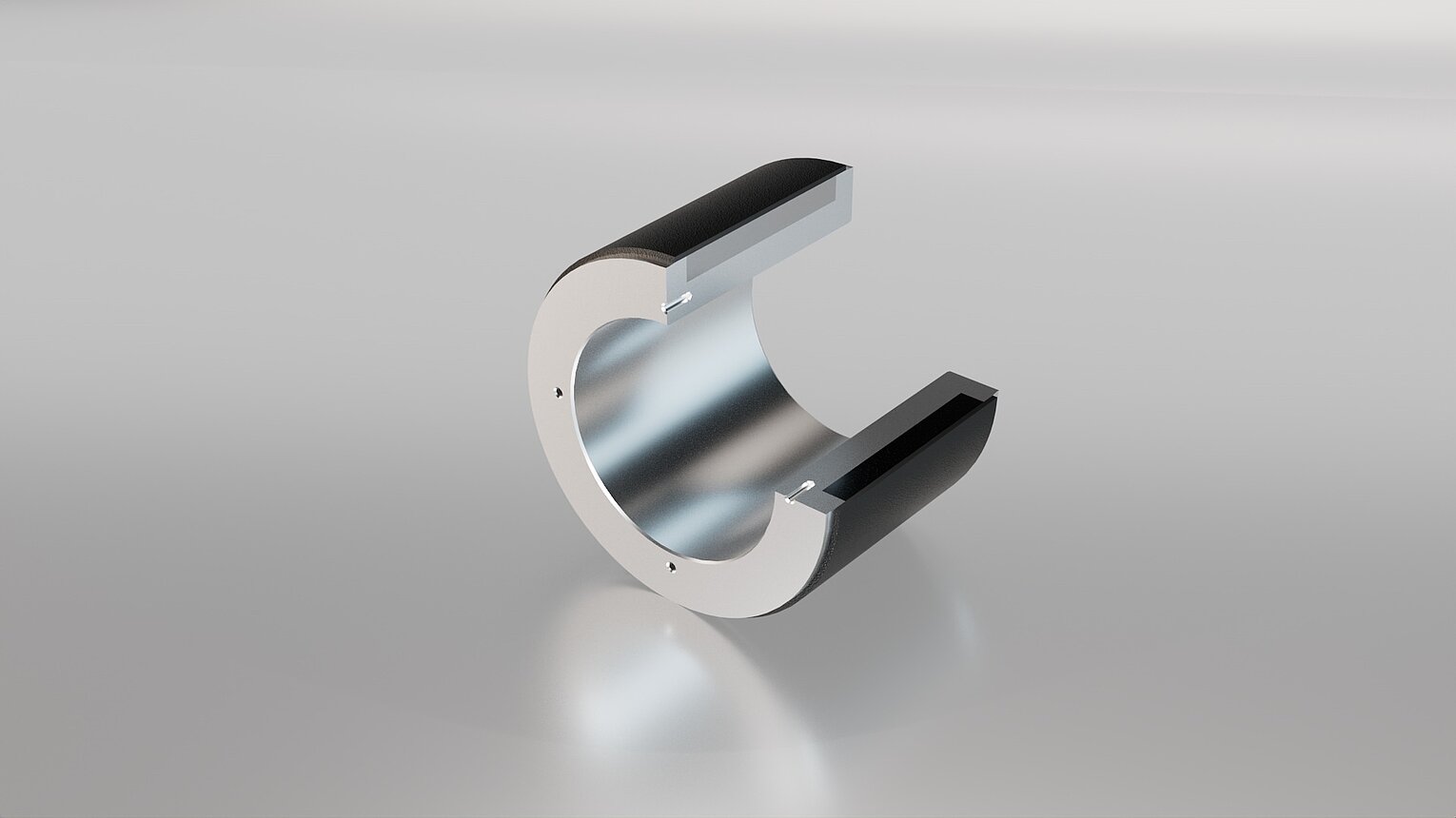

Stators

Rotors with surface permanent magnets (SPM)

Rotors with interior permanent magnets (IPM)

Synchronous rotor reluctance (SRM)

Get in touch with our specialists:

Call us on

+49 (0) 7561-98248-27

Send us a message to

m.horn(at)ate-system.de