Torque motors

High-pole synchronous motors are referred to as torque motors. Due to the high number of poles, the highest torques can be achieved in the low speed range. And highest copper filling factors are achieved, due to the winding design in the stator – this leads to low losses.

Our performance ranges for torque motors:

- Stator diameter: 21–1600 mm

- Speed range: up to 100,000 rpm

- Number of poles: up to 132

- Continuous torque: up to 60,000 Nm

Our experts are happy to assist you in your selection. Get in touch now.

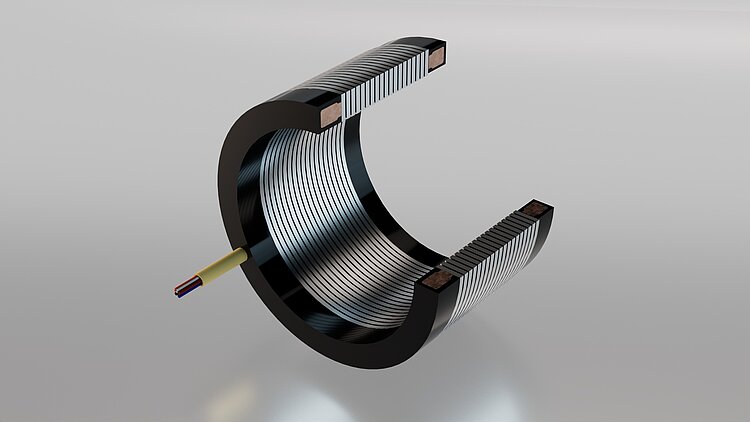

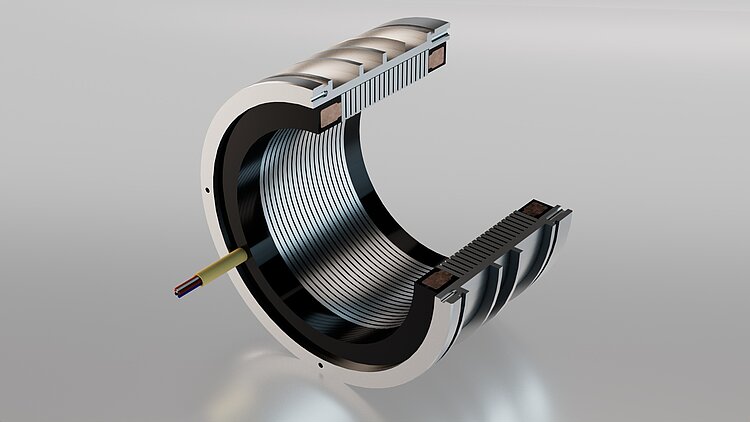

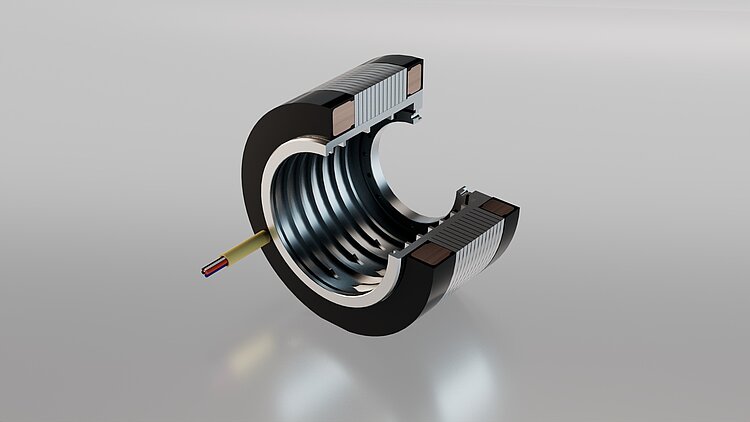

Internal rotors are the most common motor design. The rotor topology of torque motors allows an extremely large hollow shaft diameter. Due to the concentrated winding design, minimum axial winding head heights are achieved.

- Highest torque

- Highest hollow shaft diameter

- Low axial design

- Best positioning properties

- Production suitable for series production

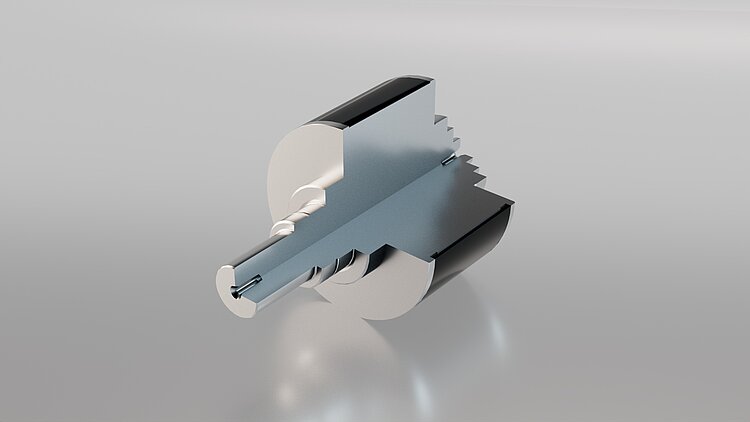

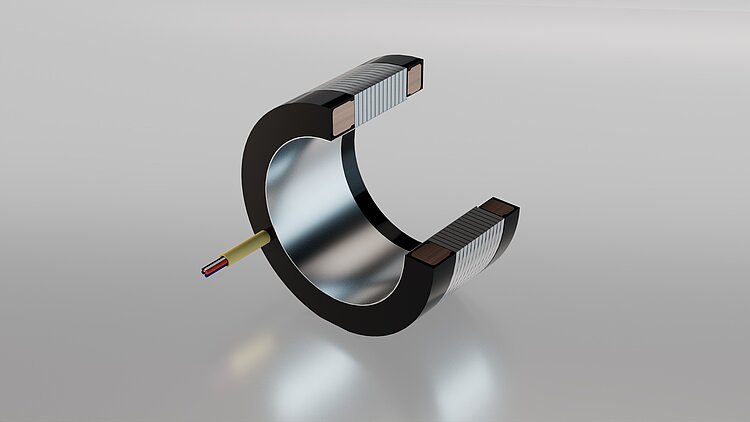

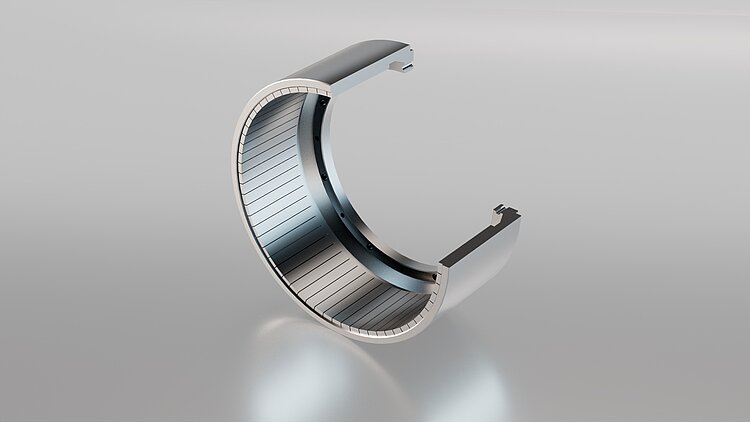

Design advantages can be achieved with external rotors as well as rhe highest shaft stiffnesses. The large air gap diameter allows high continuous torques and maximum overload cycles. Due to the concentrated winding design, minimum axial winding head heights are achieved.

- Highest torque

- Highest shaft stiffness

- Most suitable for overload cycles

- Low axial design

- Best positioning properties

Stator internal rotor

Rotor internal rotor

Stator external rotor

Rotor external rotor

Get in touch with our specialists:

Call us on

+49 (0) 7561-98248-27

Send us a message to

m.horn(at)ate-system.de

![[Translate to English:] Satort](/assets/_processed_/3/3/csm_torquemotoren_aussenlaeufer_1_Stator_d4adb43470.jpg)